Designing

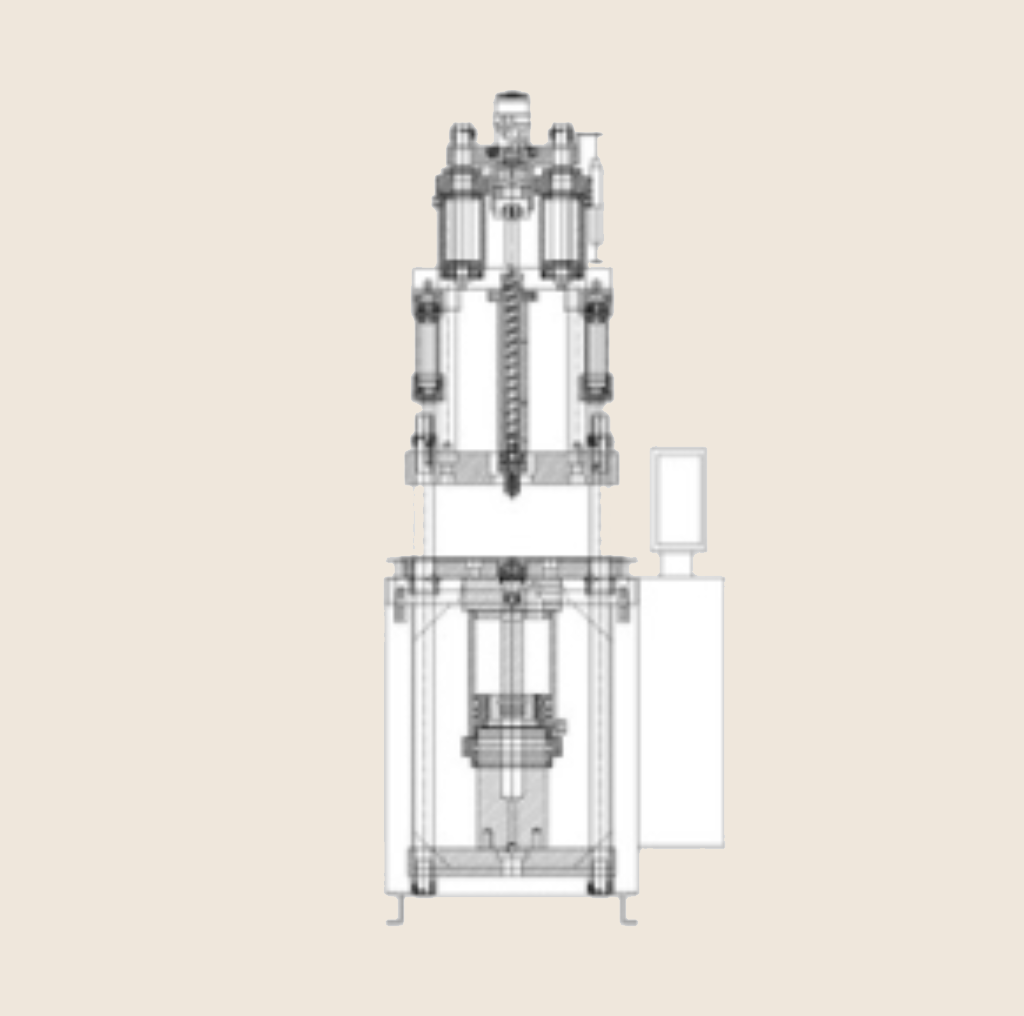

Choose Roots Polycraft, a recognised plastic injection moulding company in India, for all your product design assistance. Owing to our knowledge in plastic part design and engineering of injection moulded components, we can get every product exactly right. We utilize a scientific approach while high-end design software is used for the design of cutting-edge bespoke solutions that meet required principles and industry specifications. Each component is thoroughly tested, and many design iterations are done to ensure optimum performance. This, in turn, will enhance your operational effectiveness with your specific set of needs fulfilled. Being one of the best plastic injection moulding manufacturers in India, we ensure our design becomes the benchmark in the industry.