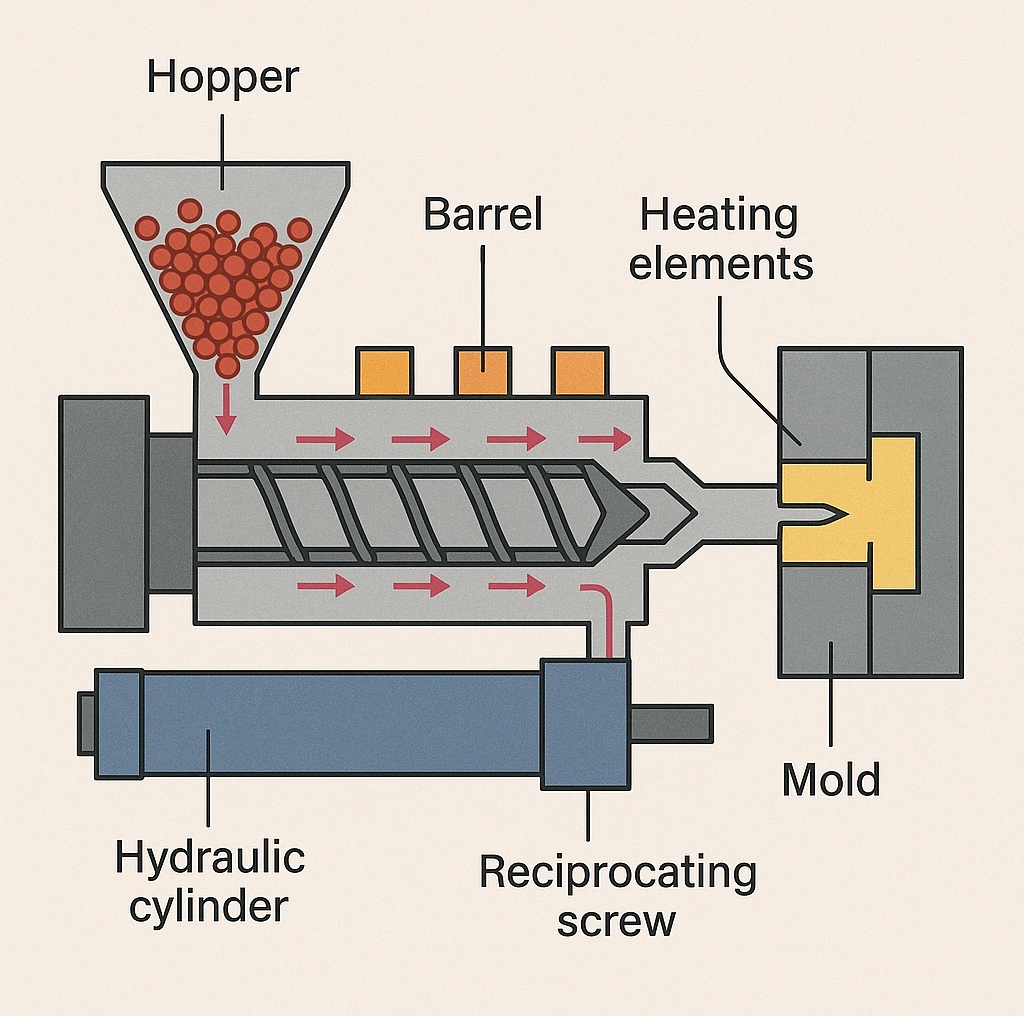

Designing

Choose Roots Polycraft, a premier injection moulding company in India, for your product design requirements. Our knowledge in plastic part design and injection moulding engineering allows us to precision-engineer every product. We employ a scientific approach and high-end design software to design cutting-edge, bespoke solutions that comply with industry specifications and standards. With repeated iterations of design and rigorous testing, we ensure each component's optimum performance, raising your operational effectiveness and fulfilling your specific needs. Being a reliable injection moulding manufacturers in India, we provide excellent designs that serve as industry benchmarks.