Benefits of Using Vertical Insert Moulding for Precision Components

What is Vertical Insert Moulding?

Vertical injection moulding is a manufacturing method that involves injecting molten plastic into a mould where pre-placed inserts (typically metal) are located. This process—insert moulding—creates strong, high-precision components in a single step.

Unlike regular injection moulding with a horizontal layout, vertical insertion systems allow gravity to help hold the insert in place, thus improving insert alignment during the moulding cycle and reducing the tendency of inserts to shift.

Why is Vertical Insert Moulding Ideal for Precision Parts?

1. Improved Strength and Durability of Components

Insert moulding combines the strength of metals and the flexibility of plastics. This creates components that resist mechanical stresses in industries like automotive, electronics, and medical devices.

2. Precise Insert Positioning

Vertical injection moulding machines have been designed to hold inserts firmly vertically. Such accuracy is essential for producing parts where the slightest misalignment can cause failure.

3. Reduced Assembly Time and Cost

One cycle of vertical insert moulding yields a finished component without further assembly steps. This reduction in such steps translates directly into lowered labour and material charges while boosting production time.

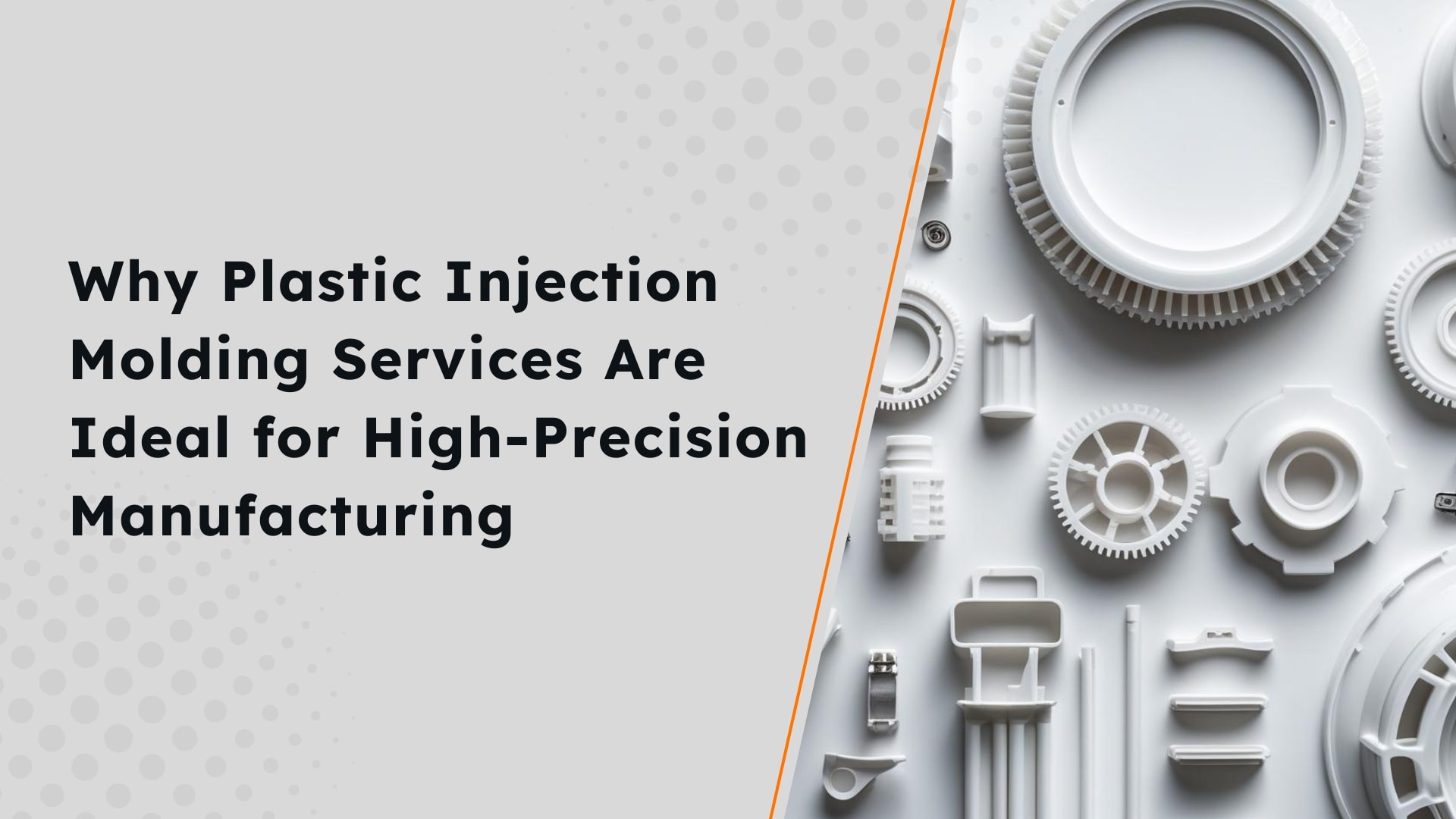

- Automotive connectors and bushings

- Electronic device casings

- Medical device housings

- Gears with embedded shafts

These applications benefit from the reliability and precision that insert moulding offers.

How Does Vertical Injection Moulding Compare to Horizontal Plastic Injection Moulding?

While both processes use plastic injection moulding, vertical systems are preferred for overmoulding and insert-based components. Traditional horizontal injection moulding is still widely used by molded plastic manufacturers for parts that don’t require inserts or gravity-assisted alignment.

What Should You Look for in a Molded Plastic Manufacturer?

Choosing the right molded plastic manufacturer is essential for high-precision parts. Look for companies that have:

- Experience in vertical injection moulding

- Experience in insert moulding

- Custom tooling capability

- Quality standards (ISO, IATF, etc.)

Conclusion

Whether you are producing electrical connectors, medical devices or components for the automotive industry, vertical insert moulding has unparalleled advantages such as accuracy, efficiency, and strength. As a tried and tested method for creating complex assemblies, vertical injection moulding is a trusted method for industries that require a consistent quality.

At Roots Polycraft, we are experts in high-quality plastic injection moulding, including vertical injection moulding and insert moulding. As a trusted plastic manufacturer, we offer components that are tailored for accuracy and performance.

Related Blogs

Today’s electronics manufacturing requires components that are as precise as...

Read More

Manufacturers require solutions that allow for precision, scalability, and superior...

Read More

Cost efficiency has been and still is king in the...

Read More

In the current manufacturing world, very few businesses are reaching...

Read More